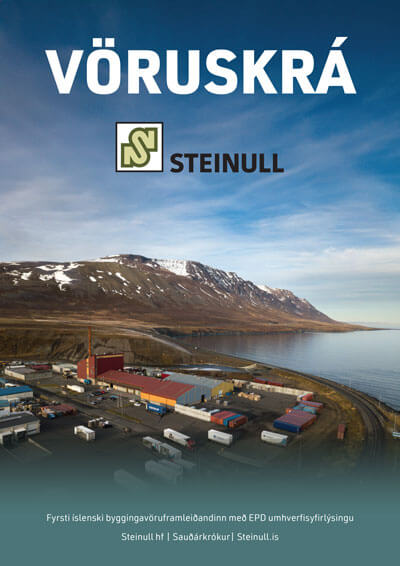

Situation and Capacity

The Icelandic mineral fiber (rock fiber) insulation factory is situated at Sauðárkrókur on the northern coast of Iceland. The factory commenced production in 1985 and it is capable of producing 10000 tons of high-class insulation per year.

Natural Renewable Recourses – Minimum Pollution

Manufacture of mineral wool is carried out on a single 1,8m wide line using electric melting. The raw material is mainly local basalt sand and crushed seashells, including proportionally small amount of dust binding oil and other ingredients. The fiber itself consists mainly of silicon oxide with number of other metallic oxides. It is bio soluble and the limiting temperature is more than 1000°C.

Not only the raw materials obtained from renewable resources, but the electrical energy used in the melting furnace and curing oven is derived from natural sources: Hydroelectric and geothermal power, neither of which emit CO2 during their generation. Because of the melting method used, emissions of waste gases from the manufacturing plant are negligible, even compared with conventional insulation plants.

ProductRange

The products are in roll, slab and loose wool form, together with rolls of foil faced ductwrap. Foil and paper faced products can be manufactured using a heated drum, and tissue facings can be applied on both sides of the insulation.

The density range is: Rolls: 20kg/m³ – 100kg/m³. Slabs: 20kg/m³ – 200kg/m³. The thickness has an extensive range from 20 to 200mm. Icerock slabs are enclosed in polythene bags, or can be supplied on pallets.

The plant is particularly flexible and versatile, there is no limit to the range of special sizes, thickness and densities which can be produced to special order within these limits. Therefor Icerock is ideally suited to the many specialist applications that involve the fabrication of non-standard products.

High Quality – Unique Properties

The unique properties of Icerock as a rock based mineral wool derive from the use of electric melting instead of the more usual coke fired rock wool cupola found elsewhere in the world. While Icerock retains those particularly important properties of rock-based products such as high limiting temperature and good compression strength, it also has the physical characteristics and quality of a glass wool. The result is a product characterised by consistent texture, low shot, low thermal conductivity, excellent resilience, low dust levels, and significantly improved handling characteristics. The Icelandic building Research Institute carries out regular independent quality control tests.

Storage and Handling

Storage and Transport

It is advisable to store the mineral-fiber wool indoors, but due to the properties of the material, it is also possible to store outdoors. When the wool is stored outdoors it should be raised on a platform with a waterproof covering to ensure that the insulation is not in direct contact with the ground surface, rain or snow.

Wool that has come into contact with water should not be used in building construction because of possible damage to other building materials or elements due to increased moisture content. Moisture or water does not damage Rockwool but it is preferable to dry it before using. It will dry out sooner if rolls or slabs are stored on edge in a dry and warm place, (indoors).

During transportation and stocking, care must be taken so that the mineral wool is not subjected to high pressures or loads. Always store denser wool under less dense wool.

Usage

Handling or usage of mineral-fiber wool is usually not injurious to health and does not require any special preventative during handling. Dust particles may occasionally produce a harmless skin itch, and therefor should personnel with catarrhal problems use a dust mask.

Cutting and shaping of mineral-fiber wool should be performed with a knife and sawing may be carried out if adequate air ventilation is available at the working place.

If working or handling mineral-fiber products does cause discomfort, the following points should be borne in mind:

· Wear clothes that do not constrict the body, especially around the wrists and neck.

· Wear gloves and mask.

· Protect the eyes.

· Collect surplus material as it arises.

· Wash under running water when the work is completed. Take care not to rub the skin.

· Wash working clothes separately from other clothes.